'Not A Simple Egg, But A Golden One’: One Day of the Poultry Farm Technologist’s Life

How can one choose the most tasty and fresh egg? What technology shall the producer follow to obtain an ideal natural product? The NUR.KZ reporters spent one day with the chief technologist at the Kazakhstani poultry farm in order to find out the answers to all the questions.

Over 300 million eggs per year – this figure is even hard to understand, but this is the quantity, which is produced by the Kazakhstani poultry farm, where Yelena Akmurzayeva is employed as a Chief Technologist.

Her main task at the enterprise is to create such conditions for the poultry and arrange the production process in such a way that each hen lays eggs in time and provides the Kazakhstani with the fresh tasty eggs. The technologist’s schedule is set up for year to come.

'Each September I make a flow process chart for the whole year. I break this chart into the cycle diagrams. It contains the scope of work per each day. The work is cyclic: they deliver us 75 000 chickens 12 times per year, it means that I make a purchase request to the company each year.

Each month 21 days prior to setting new chickens we release the poultry house: we move the grown up to 100-day hens to the mature poultry house, and the adult ones aging 560-600 days are slaughtered’, the Chief Technologist of ‘Kazger Kus’ says.

There are 16 mature poultry houses and 4 young stock poultry houses for 75 000 birds each at this poultry farm. There are 2 egg-sorting workshops and feed mill as well.

All these issues are in the custody of the Chief Technologist: she supervises the compliance with the poultry keeping, feeding, vaccination technologies, quantity of eggs laid, as well as the conditions of their sorting, packing and storage.

LAYING HENS’ LIFE IN DETAILS

The technologist brings us to a large premise: 75 000 hens are living at this poultry house in the small cages by 7-8 birds in each. The adult hens are sitting here: 96 of 100 hens lay one egg each day.

'It is impossible to go round the whole poultry farm in order to control daily, which is why I have some assistant technologists. They daily keep logs with reports, as for me, I am guided by these figures: you can see any non-compliance with technology.

We have a poultry maid and a technician in each poultry house. Although all is automated here, the poultry maid monitors all ratios such as humidity, СО2, temperature each day.

She monitors the water pressure in order it always reaches the drinking lots. The poultry maid observes the hens’ eating. The feed silo supplies feed four times a day automatically. If the poultry is not eating that means something is wrong: it does not like feed or is ill’, Yelena says.

The chickens have their special feeding regime too: they are growing up in compliance with the special feeding regime for 100 days. They are growing up not for meat, but as laying hens, that is why they are fed so that all the organs, egg tube of the poultry are well-developed and they do not fatten.

One more essential part of control is vaccination. We continuously monitor the blood of birds for diseases with the immunoassay analyzer. Usually, it is Newcastle, infectious bronchitis, rhinotraheitis and egg drop syndrome, they are vaccinated against it.

They monitor the artificial alternation of day and night in the poultry house as well. It is a special one for the hens: for the right production of gonad-stimulating hormone, which influences the egg formation.

‘It displays what temperature is inside and outside. How ventilation and heating work, what humidity is, how much feed and water the hens consumed and etc. It also displays how many hens are dead: there is a loss everyday, it is normal’, the technologist shows the separate premise with the monitoring equipment.

‘ANACONDA’ IN THE EGG-SORTING WORKSHOP

The cages in the poultry house are slope, the eggs slide down the band, which delivers them to the egg-sorting workshop. The eggs are coming to the workshop on the large and wide band – ‘anaconda’.

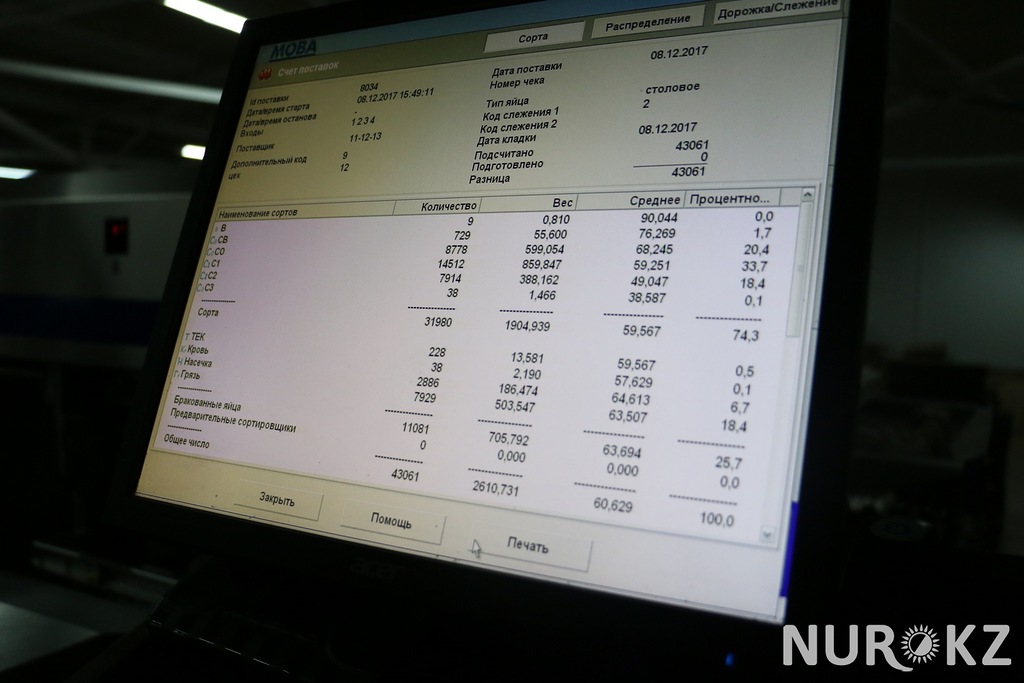

The equipment in the workshop is a special pride. The conveyor is fully automated: the only thing you have to do is to collect the ready packages with products. The Chief Technologist strictly controls all figures here as well.

‘We are the only poultry farm in Kazakhstan, which installed this equipment: it is made in Holland. We managed to implement this Project with the support from KazAgroFinance JSC, which financed the purchase of the equipment for our enterprise. Owing to this support we could bring the production to the highest level’, Yelena Akmurzayeva says.

The first stage of sorting is made manually only: the maid selects the very dirty and broken eggs in order not to make dirty the band. Further the machine does its job.

The eggs are treated by the ultraviolet against the bacteria, and then the machine separates the less dirty eggs: they will be processed as powder. The machine identifies the eggs with the micro cracks: they are taken away, since this product is dangerous for consumption. It takes away the eggs with blood: they are not dangerous, but they are not esthetical, and moreover, they are prohibited by GOST.

The eggs passed all the checks are distributed by the weight: the category is dependent on it. The products are moved by the different bands and packed.

Today, there are five categories: the highest one is from 75 gram, the selected one – 65-75 gram, С1 – 55- 65 gram, С2 – 45-55 gram and С3 – 35-45 gram. ‘Kazger Kus’ is planning to define its own categories with the difference of 5 gram and give them names instead of numbers.

OUR WAREHOUSE IS ALWAYS EMPTY

'The last control point in this cycle is the warehouse. My technologists, which are daily busy at the sites, monitor the temperature at the warehouse: it should be from 5 to 20 degree. The temperature in some places is monitored by the psychrometers: the data are registered in the log, which is handed over to me at the end of month.

We monitor the temperature so thoroughly, because when the vehicle is coming: it shall have the same temperature as the warehouse in order to avoid the egg sweating. Our warehouse is always empty: the eggs are sold out right away, because they know the quality of our products’, Yelena says.

The working day of the Chief Technologist ends at the computer: she summarizes the results on all poultry farm figures in the multi-sheet tables. The figures proves that everything is going well, and that means that the Kazakhstani people will still enjoy the fresh and tasty product labelled ‘Kazger Kus’.